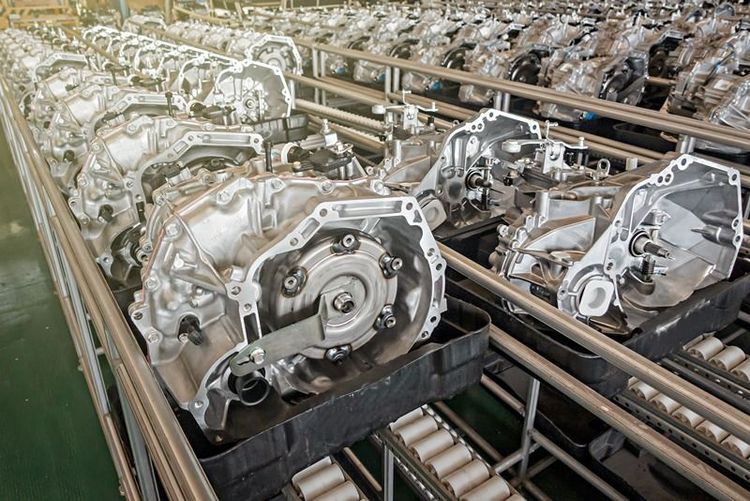

Precision and quality are crucial for the functionality and safety of components in automobile manufacturing. Indian MSMEs (micro, small, and medium enterprises) engaged in this sector must rely on materials that ensure accuracy, durability, and consistency. Cold-rolled steel has become a preferred choice for manufacturing precision auto parts due to its process characteristics and material properties. This article outlines the technical advantages of cold-rolled steel and its relevance for MSMEs procuring materials through platforms like JSW One MSME, a B2B marketplace designed for industrial and construction material requirements.

Cold-rolled steel: an overview

Cold-rolled steel is produced by further processing hot-rolled steel at room temperature. The cold rolling process compresses the material, refining its microstructure and enhancing its mechanical properties. This method delivers steel with reduced thickness tolerances, improved surface finish, and optimised strength characteristics.

+91 7208055523

+91 7208055523

Help & support

Help & support