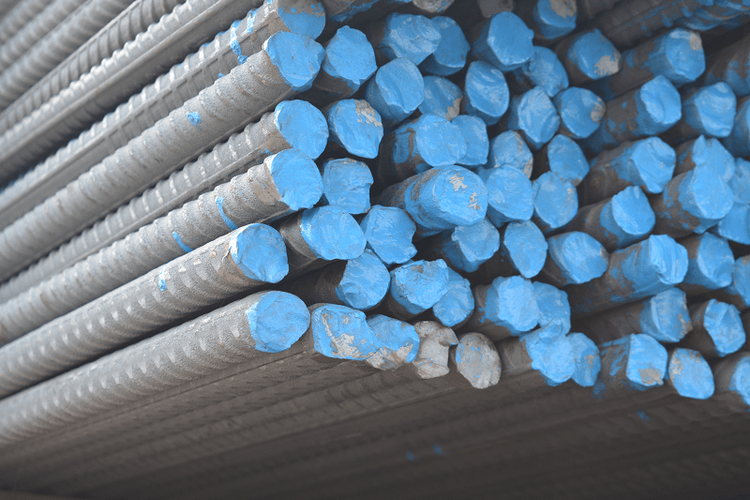

TMT (Thermo-Mechanically Treated) steel has gained immense popularity in the construction industry due to its exceptional strength, durability, and resistance to corrosion. The high-quality TMT steel is divided into primary and secondary types and is produced through a precise and complex manufacturing process that involves several stages. Primary TMT bars typically have a relatively lower tensile strength and yield strength compared to secondary TMT bars. In this comprehensive guide, we delve into each step of this process of both TMT steel:

Primary Steel

The primary steelmaking process involves the following steps:

1. Pretreatment of raw materials. The mined iron ore undergoes processing to remove impurities and improve quality. This may include crushing, grinding, magnetic separation, and/or flotation to obtain a concentrate. This is followed by sintering which means heating it to high temperatures in the presence of coke and limestone. This process produces clinker that is rich in iron.

2. Blast furnace smelting: Sintered iron ore, coke, and limestone are charged into a blast furnace. The blast furnace is a tall, cylindrical furnace that is heated by hot air blown into the bottom of the furnace. The coke burns in the blast furnace and produces carbon monoxide, which reduces iron ore to molten iron. Limestone reacts with the impurities in iron ore to form slag. This is a molten waste product removed from the top of the blast furnace.

3. Basic oxygen steelmaking (BOS): The molten iron from the blast furnace is transferred to a BOS furnace. In the BOS furnace, oxygen is blown through the molten iron, which oxidises the carbon and other impurities in the iron. This process lowers the iron carbon content and produces molten steel.

4. Alloy addition: The molten steel from the BOS furnace may be alloyed with other elements, such as manganese, chromium, and nickel. These alloying elements are added to the molten steel to give it the desired properties.

5. Casting: Molten steel is then cast into moulds to produce ingots or slabs. The ingots or slabs are then further processed to produce the desired finished steel products.

+91 7208055523

+91 7208055523

Help & support

Help & support