Factors affecting uniform gauge and dimension in TMT bars

Several factors influence TMT bars' gauge and dimensional accuracy, including: Manufacturing precision: High-quality rolling mills equipped with advanced technology ensure consistent diameter and weight across the bar's length. Automated processes minimise human error, thus ensuring uniformity in core diameter throughout the bars. Raw material quality:

The consistency of the steel billet used in the production of TMT bars plays a significant role in maintaining dimensional accuracy. Impurities or inconsistent material properties can lead to irregularities during rolling. Process control: The rolling process, followed by quenching and self-tempering, must be closely monitored to avoid deviations. Modern mills use computerised control systems to achieve precise tolerances. Quality testing: Reputable manufacturers conduct rigorous testing to ensure dimensional uniformity. Parameters such as diameter variation, weight per metre, and cross-sectional consistency are checked to meet IS 1786:2008 standards.

Impact of uniform gauge and dimension on construction quality

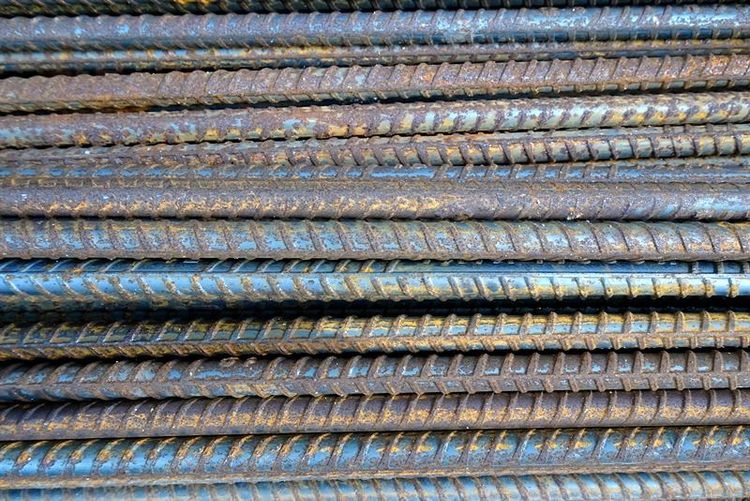

Uniformly gauged TMT bars ensure consistent rib patterns, which improve their grip on concrete. This bonding is critical for effectively transferring loads between the steel and concrete, enhancing overall structural strength.

Accurate dimensions ensure that the calculated quantities of steel are sufficient for the project. Overweight bars lead to unnecessary costs, while underweight bars may compromise safety.

Uniform TMT bars distribute stress evenly during seismic events, enabling the structure to absorb and dissipate energy more effectively.

Variations in gauge can create challenges during construction, such as difficulties in bending, tying, or placing the bars. Uniform dimensions ensure smoother operations and reduce labour costs.

Uniformly gauged TMT bars ensure adherence to IS standards and project specifications, minimising the risk of penalties or delays due to non-compliance.

Key considerations for MSMEs when procuring TMT bars

For MSMEs, procuring TMT bars with consistent gauge and dimensions is essential for achieving cost-efficient and high-quality construction. Here are a few considerations:

Choose suppliers or platforms like JSW One MSME, which ensure that all TMT bars meet stringent quality standards, including dimensional accuracy.

Ensure that the TMT bars are certified as per IS 1786:2008, which specifies the requirements for physical and chemical properties, including dimensional tolerances.

Inspect batch test reports or manufacturer’s documentation for details on diameter variation, weight per metre, and other critical parameters.

B2B marketplaces like JSW One MSME provide detailed product specifications, enabling MSMEs to make informed purchasing decisions. These platforms also offer logistical and credit support, simplifying procurement.

+91 7208055523

+91 7208055523

Help & support

Help & support