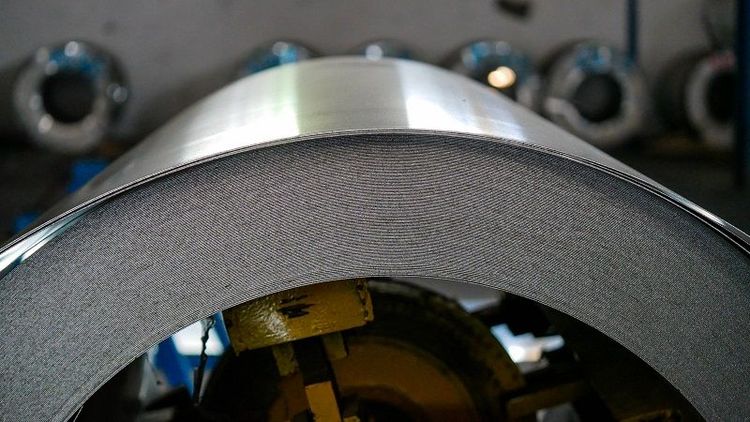

Mild steel is low-carbon steel made from iron and carbon. It is an inexpensive steel category with properties suitable for most general engineering applications. Due to its high iron content, mild steel has excellent magnetic properties; it is therefore defined as being 'ferromagnetic'.

The carbon content in mild steel ranges between 0.16% and 0.29 % and has a relatively higher melting point between 1450°C to 1520°C. This melting point means that mild steel is more ductile when heated, making it especially suitable for drilling, cutting, forging, and welding, thus easy to fabricate. Register with us to ensure you get the best mild steel for all your fabrication requirements.

However, mild steel is not that suitable for hardening. Only in some instances can it be hardened by heating it, adding a chemically reactive carbon source to it, and the subsequent quench cycle will harden the surface layer.

Mild steel does not have good corrosion resistance in an untreated form, which, however, can be improved to a significant extent by applying an appropriate surface protection product to the exposed parts of the project. Several options are available in the market to enhance the appearance of mild steel and protect it from rust and corrosion, like red oxide primers, metal paint, metal spray paint, and zinc treatments.

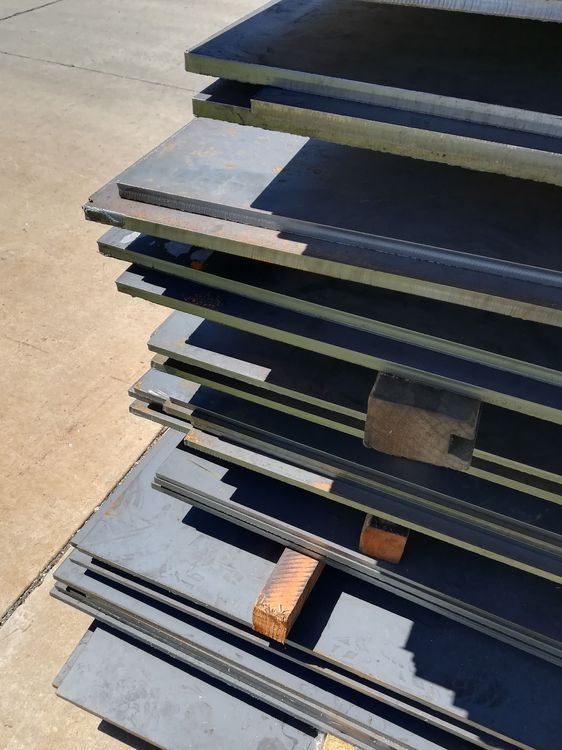

This category of steel is graded as per its chemical composition, the way it is produced, and its properties, so you will have many options of mild steel to choose from basis your requirements. This article will discuss the three most widely used types of Mild steel.

+91 7208055523

+91 7208055523

Help & support

Help & support