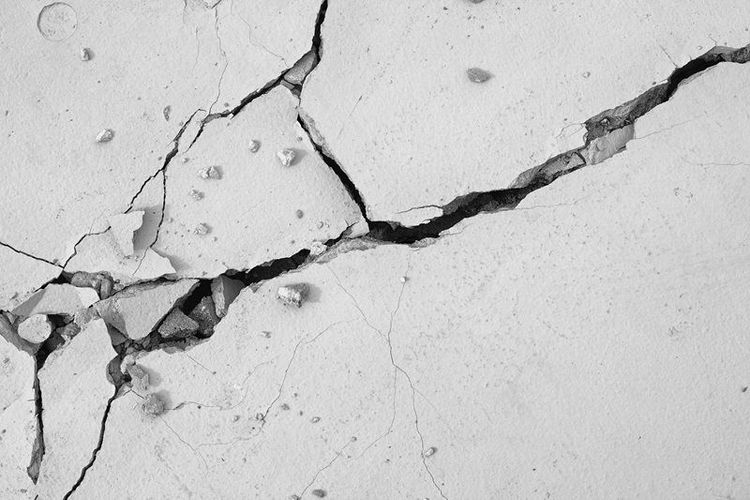

Common types of cracks

Shrinkage cracks: These result from water evaporation or chemical reactions during concrete setting.

Settlement cracks: They are caused by soil movement or improper compaction beneath the concrete.

Thermal cracks: These stem from temperature fluctuations leading to expansion and contraction.

Plastic shrinkage cracks: They occur due to rapid moisture loss in the initial curing stages.

Corrosion-induced cracks: They arise from the rusting of embedded steel reinforcement. One can opt for JSW Power Pro Cement, which is known to protect from corrosion and involves less maintenance cost.

Causes of cement cracks

Shrinkage

The natural process of concrete drying leads to shrinkage, causing cracks if not managed effectively.

Poor concrete mix design

Incorrect cement, sand, aggregate ratios and improper curing techniques contribute to crack formation.

External factors

Temperature variations and environmental conditions, like excessive moisture or humidity, play a significant role in crack development.

Structural issues

Inadequate reinforcement and overloading can strain the concrete, leading to cracks over time. Hence, quality assurance should accompany the search for the best price on cement

Detecting Cement Cracks

A. Visual Inspection

Visual inspection is crucial in detecting cement cracks by identifying different crack patterns. This method involves visually examining the surface of concrete structures to determine the type, direction, width, and depth of cracks. Other types of cracks, like plastic shrinkage cracking, crazing, hairline cracking, D-cracking, and offset cracking, can be observed and analysed to understand the underlying causes and severity of the cracks

+91 7208055523

+91 7208055523

Help & support

Help & support