TMT (thermo-mechanically treated) steel undergoes a thermo-mechanical treatment process, giving them higher strength and better flexibility than traditional hot-rolled steel. These are often preferred for constructions requiring bending or shaping, like building columns or beams. On the other hand, TMX (thermo-mechanically treated extended) bars take this a step further with an extended thermo-mechanical treatment process. Then there are HYSD (high yield strength deformed) bars, which subject mild steel to hot or cold working processes followed by quenching and tempering. Understanding the differences between these materials is essential in construction and engineering because it helps engineers choose the right type of steel bar for the specific requirements of their project.

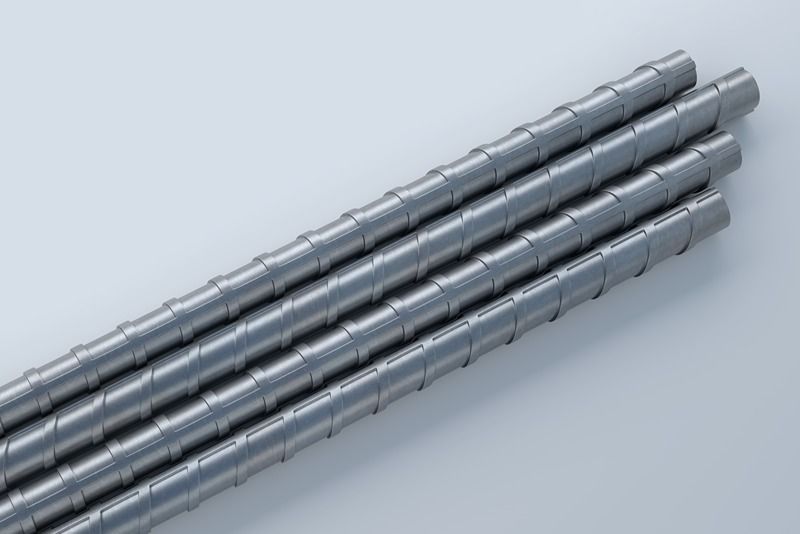

TMT bars

- TMT bars are manufactured using a unique controlled cooling process after rolling.

- This treatment imparts higher strength to the bars than traditional hot-rolled steel bars.

- TMT bars have better ductility and bendability, making them suitable for construction where flexibility is required.

- They also have excellent corrosion resistance, making them suitable for use in areas with high humidity or exposure to corrosive elements. For example, the superiority of JSW One TMT rebars can be attributed to their comprehensive engineering and adherence to Bureau of Indian Standards (BIS) specifications. Unlike the numerous TMT bars available, which often fail to meet quality standards and are unsafe for construction, JSW One TMT rebars stand out for their exceptional quality and performance.

+91 7208055523

+91 7208055523

Help & support

Help & support