Cold-rolled steel is an important material due to its strength, ductility, and other mechanical properties. Grain boundaries, which are the interfaces between adjacent grains, play an important role in determining these properties. We examine how grain boundaries influence the mechanical properties of cold-rolled steel, shedding light on their role in controlling strength and durability.

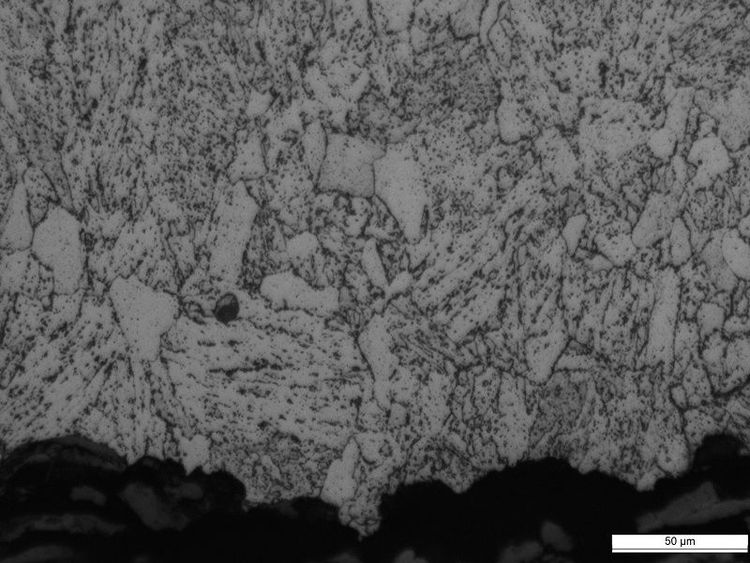

Grain boundaries can be defined as the interfaces between adjacent crystallites or grains in a polycrystalline material. They are generally classified into two main categories, high-angle and low-angle grain boundaries, based on their respective misorientation angles.

Influence of grain boundaries on mechanical properties of cold-rolled steel

Grain boundaries in cold-rolled steel are formed during the manufacturing process and play a significant role in the material's mechanical properties in the following ways:

Strength enhancement: The material of grain boundaries can be strengthened by reducing dislocation motion. Linear defects called dislocations in crystals cause plastic deformation. Dislocation movement is restricted by grain boundaries, which also increases the material's strength.

Grain size refinement: Steel grain size decreases during cold rolling. Greater density of grain boundaries is caused by smaller grain sizes. Greater strength and hardness are obtained as a result of the increased barriers to dislocation motion that larger grain boundaries give.

Ductility and toughness: The way grains are arranged in cold-rolled steel affects its ability to stretch and its toughness. When grains slide past each other along the boundaries, it allows the steel to bend without breaking, making it more flexible. However, some grain boundaries can actually cause cracks to start and spread, making the steel less tough. How the grain boundaries behave determines the balance between the steel's ability to stretch and its toughness.

Grain boundary corrosion: When steel is cold rolled, the size of its grains becomes smaller. This means that there are more boundaries between the grains. These boundaries make the steel stronger and harder because they create obstacles that prevent the movement of defects within the steel.

+91 7208055523

+91 7208055523

Help & support

Help & support