The industrial and machinery industry faces increasing pressure to meet stringent emission standards as governments and regulatory bodies push for sustainable manufacturing. Industries reliant on heavy machinery and steel components must adopt strategies that reduce carbon footprints while maintaining operational efficiency. Advanced steel solutions provide an effective way to meet emission standards, offering durability, recyclability, and energy-efficient applications.

How steel solutions help in reducing emissions

Steel plays a critical role in helping industries achieve compliance with environmental regulations. High-strength and lightweight steel materials contribute to energy efficiency by reducing fuel consumption in machinery and transport applications. Advanced manufacturing techniques such as electric arc furnace (EAF) and Induction Furnace steel production which primarily use good quality recycled material and restricts use of coke further reduce emissions compared to traditional blast furnace methods.

Low-carbon steel variants and coatings enhance sustainability by lowering the carbon footprint during production and application. Recycled steel, which retains the same structural integrity as virgin steel, significantly reduces energy consumption and emissions in the manufacturing process due to minimal use of coke. Moreover, innovations in high-performance alloys allow industrial equipment to last longer, reducing the need for frequent replacements and minimising waste.

Key steel applications for emission compliance

- High-strength steel for lightweight componentsUsing advanced high-strength steel (AHSS) allows industries to manufacture lightweight machinery and components, leading to lower fuel consumption and reduced emissions.

- Energy-efficient manufacturing processesSteel production using electric arc furnaces (EAF) cuts emissions by utilising scrap metal rather than raw iron ore, reducing carbon output and energy consumption.

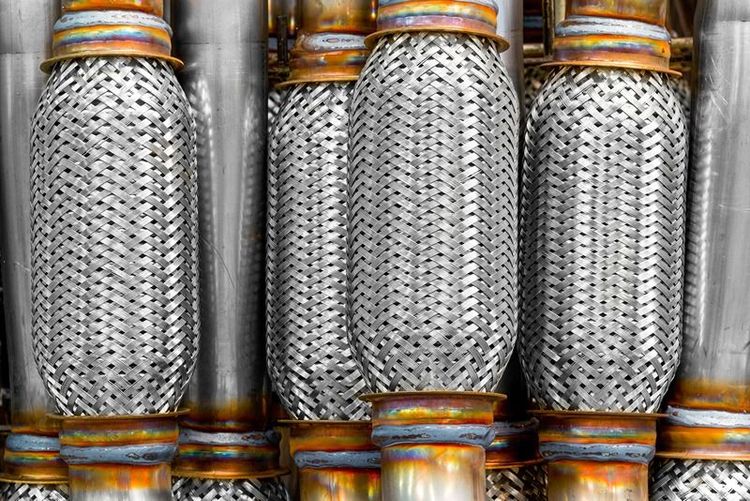

- Corrosion-resistant coatingsStainless and galvanised steel coatings extend the lifespan of industrial machinery, reducing material waste and decreasing emissions associated with frequent manufacturing and replacement cycles.

- Recyclable and low-carbon steel Industries adopting recyclable steel reduce their environmental impact by limiting raw material extraction and reducing industrial emissions during processing.

- Heat-resistant and low-emission alloys Steel alloys with improved thermal resistance enhance efficiency in high-temperature industrial applications, minimising energy loss and optimising fuel use.

+91 7208055523

+91 7208055523

Help & support

Help & support