Stainless steel remains a popular alloy of choice for MSMEs in industries like food & catering, offshore oil & gas, water desalination, construction, power generation, shipbuilding, chemicals, medical equipment, and storage tanks. It can support incredibly heavy loads without risking fracture and is capable of being easily moulded to suit a wide range of business applications. Moreover, with stainless steel, there is a complete range of sizes and designs to pick from, so it’s highly “versatile.”

Stainless steel: A true story of strength and resilience

Stainless steel products that have reached the end of their useful lives can be melted down and their constituent elements reclaimed and reused in new steel products without any adverse impact on performance. In fact, the recovery rate in recycling for stainless steel is close to 100%. According to the Steel Recycling Institute, one ton of recycled steel saves 2,500 pounds of iron ore, 1,400 pounds of coal, and 120 pounds of limestone. Versatility, tensile strength, and recyclability are the key factors responsible for stainless steel’s undying popularity after more than a century of existence!

What makes stainless steel so great?

Stainless steel is essentially a low-carbon steel alloy comprising mostly iron, along with chromium (at least 10.5%) and, in some cases, other elements like nickel, molybdenum, silicon, and manganese in varying degrees. It’s the addition of chromium and other elements that accounts for the alloy’s incredible resistance to staining and corrosion. Chromium hardens stainless steel and gives it the ability to withstand wear and tear, pressure, or damage even at high temperatures, depending on its grade. As soon as the alloy is exposed to oxygenated environments, the chromium reacts with ambient oxygen to form a thin invisible and tight film of chromium oxide, thus saving the underlying metal surface from corrosion.

All grades of stainless steel can support heavy loads without risking fracture. Certain grades can resist sub-arctic temperatures (-40°C) and extreme heat (870°C or higher)! Stainless steel is the preferred alloy for MSME manufacturers of medical equipment and devices because it is easy to sanitise and rid its surface of contaminants. Stainless steel medical tools with anti-bacterial coating can prevent infections or keep them in check.

Stainless steel is an umbrella term that applies to as many as 100 different grades of steel. Broadly, stainless steel falls into five groups (families).

Austenitic stainless steel

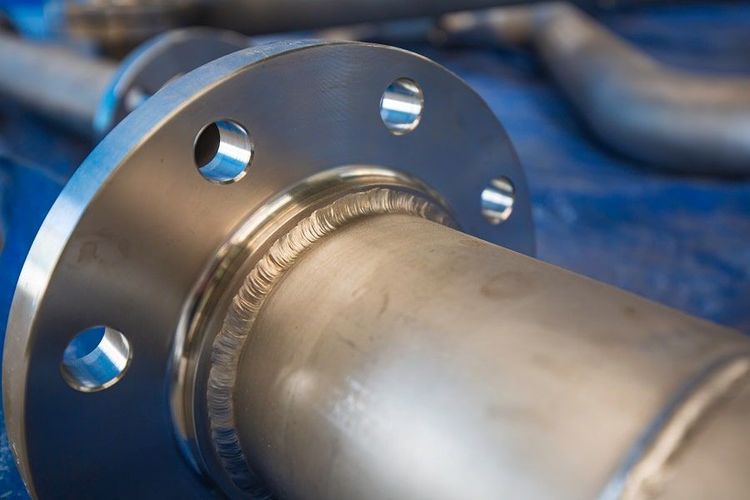

This is the largest, most common type of stainless steel, named after Sir William Chandler Roberts-Austen. Austenitic stainless steel contains 16-26% chromium and up to 35% nickel and exhibits high resistance to heat and corrosion. Austenitic stainless steel can be easily welded or reformed without cracking or folding. However, it cannot be hardened by heat treatment.

“300 series” austenitic stainless steel is not just corrosion resistant but also maintains its strength at high temperatures. Grade 304 is the most widely used of all stainless steels and is most commonly utilised in high-temperature scenarios like cookware and heat transfer plates. Applications include medical equipment, automotive parts, springs, cutters, razor blades, jet engine components, and landing gears.

Ferritic

Ferritic contains 10.5-30% chromium and low carbon content (less than 0.20%). It works out cheaper than austenitic and duplex steels and possesses good ductility and corrosion resistance. It can be transformed into complex shapes without the application of heat (cold working, deep drawing). Applications includes automotive parts, industrial machinery, and kitchen ware.

Martensitic

Chromium makes up 11.5-18% of this stainless steel and carbon, 0.61-1.50%. In this respect, martensitic is similar to ferritic. However, martensitic has a higher carbon content than ferritic, and this gives it a special structural robustness. It is low on nickel; therefore, from a corrosion resistance standpoint, martensitic steels are weaker than other types of stainless steel.

“400 series” stainless steels are made of martensitic (or ferritic stainless steel) and these tend to be stronger and more wallet-friendly than the 300 series though less resistant to corrosion. Grade 410 is the most popular of these and demonstrates good strength, hardness, and stress resistance. It is mostly seen in contexts that require high mechanical properties and moderate corrosion resistance such as in pumps, gas turbine blades. Its applications include medical devices, bearings, cutlery, turbine blades.

Duplex

At a granular level, duplex is roughly a 50:50 mix of austenite and ferrite and displays the properties of both. Typically, it is twice as strong as regular austenitic steels and, in a lot of cases, tougher than ferritic. It has high corrosion resistance. However, it is often difficult to cut duplex sheets into desired shapes and sizes owing to their toughness. Besides, they are not quite as easy to weld as austenitic steels. Applications would include cargo tanks, stainless steel pipes and tubes, heat exchangers, digesters, biofuel plants.

Precipitation hardened

Austenitic and martensitic steels are “precipitation hardened” by applying a series of heat treatments to make them stronger, tougher, and highly corrosion resistant. Austenitic steel is heated to less than 2050°F, then cooled slowly. It is next reheated, and during this treatment precipitates like copper, aluminium, and titanium are added to enhance corrosion resistance. Martensitic stainless steels are also precipitation hardened via a similar process. The difference is that these are heated to less than 1950°F. Its applications include Nuclear waste casks, aerospace engine components, turbine blades, gears.

JSW One MSME is a one-stop digital market space for stainless steel sheets and coils of various grades. At JSW One MSME, you can pick from a wide range of not just hot-rolled and cold-rolled stainless steel but virtually all steels - Coils, sheets, wire rods, colour-coated steel. Order online and get your supplies delivered. You can be rest assured that you are dealing with trusted suppliers as our platform features 100% verified sellers. Our steel prices are clear and transparent.

Buy online

Mild SteelStructural SteelTMTCementJSW One MSME

About usBlogsSitemapJSW One TMTPolicy

Terms & conditionsPrivacy policyReturn policyBanking partner

+91 7208055523

+91 7208055523

Help & support

Help & support