From January to December 2021, India became the second largest producer of crude steel worldwide, with a total production of 118.20 Million Tonnes (MT) and a 17.9% growth rate compared to the same period in 2020. India also ranks as the second largest consumer of finished steel, with a consumption of 106.23 MT in the year, following China as the largest steel consumer based on the World Steel Association's data.

The proportion of carbon plays a pivotal role in determining the steel's properties. Generally, the carbon content in steel can range from as low as 0.02% to as high as 2.1%. This variation gives rise to different types of steel, each with distinct characteristics.

The effects of carbon on steel

Importance of carbon content in steel for industrial applications

1. Strength and hardness:

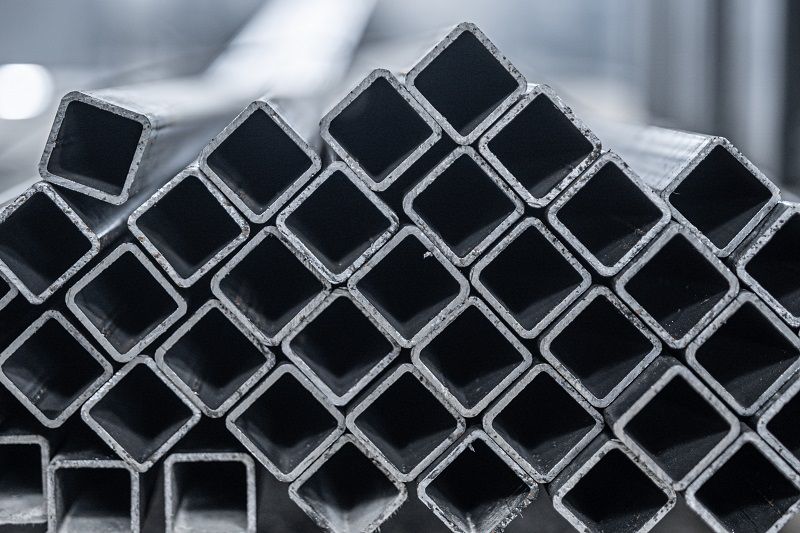

Low-carbon steel: Steel with low carbon content (typically less than 0.3%) is known for its exceptional ductility and malleability. They are easy to weld and form, making them suitable for construction, pipe and tubes, and automotive manufacturing applications.

Applications:

- Structural components: Mild steel is commonly used for construction purposes, such as beams, columns, and structural supports.

- Automobile components: It produces car bodies, chassis, and various automotive parts.

- Machinery parts: Mild steel is suitable for manufacturing gears, nuts, bolts, and other machine components.

- Pipes and tubing: It's often used for plumbing and manufacturing pipes and tubing.

Medium carbon steel: Carbon content from 0.3% to 0.6% increases strength and hardness. Medium carbon steel is often used in forging and structural applications.

Applications:

- Shafts and axles: Medium carbon steel's strength and toughness make it suitable for producing shafts, axles, and crankshafts.

- Rails and railway tracks are used to construct railroad tracks and other transportation infrastructure.

- Springs: Medium carbon steel is often used to make springs, including coil springs and leaf springs.

- High-strength fasteners: Bolts, nuts, and studs requiring greater strength and wear resistance are often made from medium carbon steel.

High carbon steel: With carbon content exceeding 0.6%, high carbon steel is tough and strong. This steel finds applications in making tools, springs, and cutlery, where hardness and wear resistance are critical.

Applications:

- Cutting tools: High carbon steel is used to manufacture chisels, knives, saw blades, and drills because of its hardness and ability to hold a sharp edge.

- Springs: It's used for high-performance springs in automotive suspension systems and industrial machinery applications.

- Wire and cables: High carbon steel wire is used for applications like piano wires, guitar strings, and wire ropes due to its strength and flexibility.

- Blades and cutting edges: High-carbon steel produces high-quality blades, including swords, razors, and surgical instruments.

2. Ductility and toughness:

As carbon content increases, ductility tends to decrease. High carbon steel, while incredibly strong, are less ductile and can become brittle if not properly heat-treated. Alloying elements such as manganese can help balance the trade-off between strength and ductility in higher carbon steel.

3. Weldability:

Low-carbon steel is easily weldable due to its excellent ductility and low risk of cracking during welding. On the other hand, high-carbon steel requires careful preheating and post-welding heat treatment to prevent brittleness.

4. Corrosion resistance:

Carbon itself doesn't contribute to corrosion resistance, but adding elements like chromium and nickel can enhance a steel's resistance to corrosion. Stainless steel, for instance, contains a significant amount of chromium to resist rust and staining.

5. Heat treatment:

Carbon content determines how steel responds to heat treatment processes like quenching and tempering. High carbon steel can be hardened and tempered to achieve the desired balance of hardness and toughness.

Alloy steel

Alloy steel is a highly adaptable type of steel that contains not only different levels of carbon but also other alloying elements. These elements include chromium, which strengthens and toughens the steel while also increasing its resistance to corrosion. Nickel is also added to improve resistance against corrosion and oxidation at high temperatures. Molybdenum is another element added to increase hardenability, toughness, and tensile strength. Lastly, vanadium is used to refine the grain structure of steel, which enhances its strength, toughness, and wear resistance. The carbon content in alloy steel can vary widely, depending on the desired characteristics. When you buy steel online, you see steel alloys applications in many industries, from aerospace and automotive to construction and manufacturing.

The influence of carbon on microstructure

Ferrite: Low-carbon steel primarily consists of ferrite, a soft, ductile phase. The low carbon content allows for the formation of numerous ferrite grains, which contribute to the steel's malleability. It is highly magnetic and has high electrical resistance making it desirable for antennas and transformers.

Cementite: High-carbon steel, conversely, has a microstructure rich in cementite, a hard and brittle phase. The increased carbon content forms fewer but larger cementite particles, resulting in greater hardness and reduced ductility.

Martensite: When high-carbon steel is rapidly cooled (quenched) from a high temperature, it transforms into martensite. This phase is exceptionally hard but brittle, making it ideal for cutting tools and knife blades.

Conclusion

The effects of carbon on steel are nothing short of remarkable. From the malleable and ductile low-carbon steel used in everyday products to the tough and sharp high-carbon steel found in precision instruments, carbon content plays a pivotal role in determining steel's properties. Additionally, alloy steel opens up possibilities by combining carbon with other elements to create materials tailored to meet specific industrial needs. Understanding these variations in carbon content and microstructure allows us to harness the full potential of this incredible material, making it an enduring cornerstone of modern civilization.

Buy online

Mild SteelStructural SteelTMTCementJSW One MSME

About usBlogsSitemapJSW One TMTPolicy

Terms & conditionsPrivacy policyReturn policyBanking partner

+91 7208055523

+91 7208055523

Help & support

Help & support