Stainless steel is a versatile and popular material known for its durability and aesthetic appeal. One of the most coveted finishes for stainless steel surfaces is the mirror finish, which provides a glossy, reflective appearance. Achieving a mirror finish requires careful preparation, attention to detail, and the right techniques.

In this comprehensive guide, we will walk you through the step-by-step process of achieving a mirror finish on stainless steel.

1. Understanding Stainless Steel and its Characteristics

Stainless steel is an alloy composed of iron, chromium, and other elements, such as nickel and molybdenum. The exact composition may vary depending on the specific grade of stainless steel. The addition of chromium creates a protective layer of chromium oxide on the surface of the steel, which gives stainless steel its exceptional corrosion resistance.

Different grades of stainless steel have varying amounts of chromium and other alloying elements, resulting in different properties. Some grades are more suitable for achieving a mirror finish due to their enhanced polishability. For example, austenitic stainless steels, such as 304 and 316, are commonly used for their excellent corrosion resistance and polishability. Ferritic and martensitic stainless steels are generally less suitable for achieving a mirror finish due to their lower chromium content and higher hardness.

Understanding the composition and properties of the specific grade of stainless steel you are working with is crucial in selecting the right approach and techniques for achieving a mirror finish. It helps determine the appropriate polishing compounds, equipment, and processes that will yield the best results.

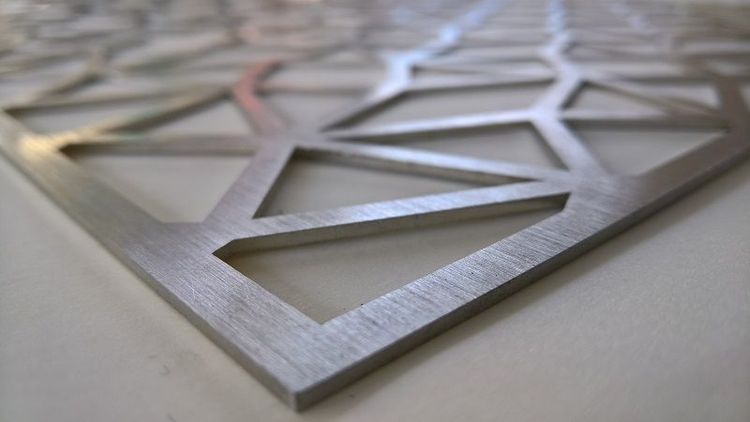

2. Surface Preparation

Proper surface preparation is vital for achieving a mirror finish on stainless steel. The surface must be clean, free from contaminants, oils, and residues that can interfere with the polishing process. Surface preparation typically involves a combination of cleaning, sanding, and grinding.

Cleaning the stainless steel surface thoroughly using suitable cleaning agents removes dirt, grease, and other impurities. It is important to use cleaners that are specifically formulated for stainless steel to avoid damaging the surface. After cleaning, the surface may be passivated to remove any embedded iron particles and restore the protective chromium oxide layer.

Sanding and grinding techniques are then employed to eliminate scratches, imperfections, and unevenness. Starting with coarser grits, such as 120 or 180, and gradually progressing to finer ones, such as 320, 400, and beyond, helps achieve a smoother surface. The use of sanding discs, belts, or abrasive pads in conjunction with sanding machines or hand tools ensures consistent and controlled material removal.

Surface preparation is a critical step as it ensures that the subsequent polishing stages are effective and yield the desired mirror finish. It creates a clean and uniform base for the polishing compounds to work on, enhancing the overall results.

+91 7208055523

+91 7208055523

Help & support

Help & support