Steel wire rods find application in steering and suspension systems, gears, fasteners, shafts, fuel injectors, tyre cords, and bearings, contributing to vehicles' overall performance and safety. Yet, not all wire rods are created equal, and advancements in production technologies hold the potential to enhance automotive functionalities while reducing costs.

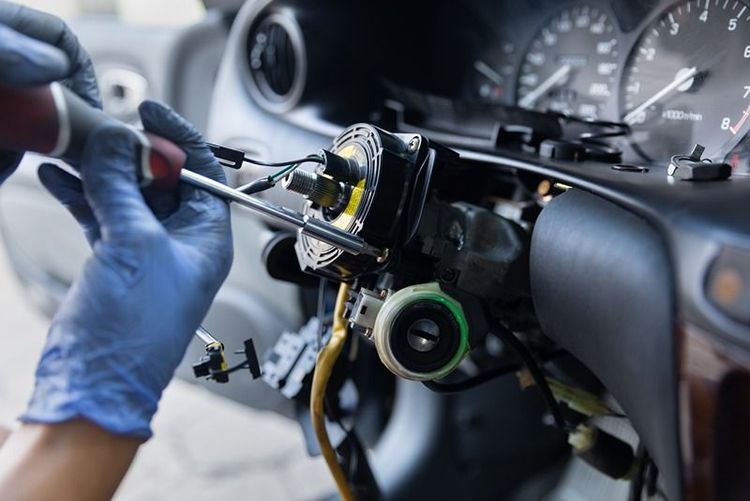

In the steering system, wire rods are crucial in facilitating smooth wheel movement with minimal effort from the driver. Traditionally, components like the pinion shaft and tie rod require heat treatment during production. For suspension systems, wire rods must possess high tensile strength and fatigue resistance to ensure optimal control and comfort for drivers.

Tyre cords, derived from wire rods, reinforce tyres, providing strength and puncture resistance. The wire rods on JSW One MSME meet stringent criteria for strength, elongation, and stiffness, contributing to product durability and road grip.

+91 7208055523

+91 7208055523

Help & support

Help & support