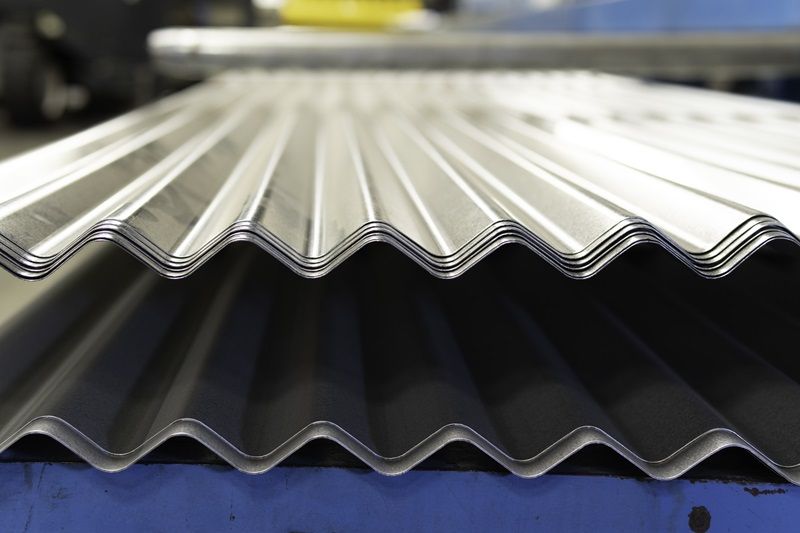

Signs of wear and damage

Galvanised metal, despite its resilience, exhibits clear indicators of wear. Look for telltale signs such as rust spots, white or powdery residue, or uneven discoloration across the surface. These visual cues often signal underlying corrosion, compromising the metal's protective zinc layer. Moreover, pitting or flaking may become apparent, indicating a weakened structure . Exposure to elements like moisture, extreme temperatures, and chemicals accelerate this deterioration, gradually diminishing both the appearance and structural integrity of the galvanised iron sheet.

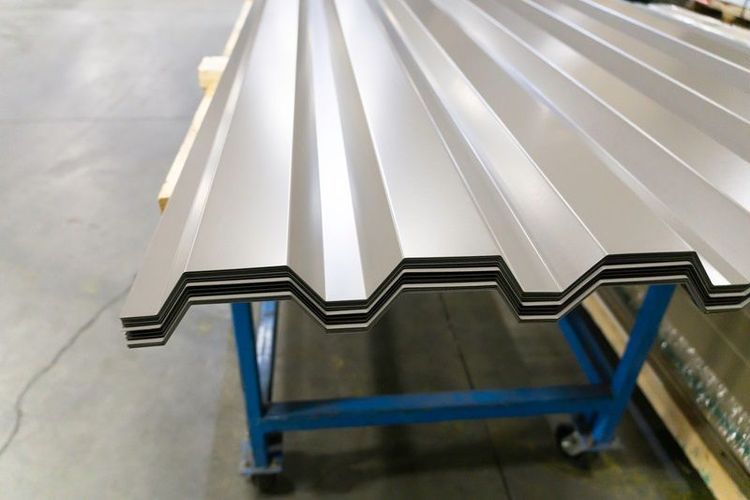

Tools and materials needed

Restoring galvanised metal roofing sheets requires specific tools and materials tailored to tackle its unique characteristics. Among the essentials are protective gear like gloves, goggles, and a respirator to ensure safety during the restoration process. Wire brushes or abrasive pads aid in the removal of rust and debris without damaging the underlying zinc coating. Additionally, mild detergents or vinegar serve as effective cleaning agents, crucial for prepping the surface.

When it comes to coatings, opt for galvanised metal primers or epoxy-based paints designed to adhere to galvanised iron sheets, providing long-lasting protection against corrosion. Each tool and material plays a pivotal role in achieving a thorough and durable restoration, safeguarding the metal against further deterioration.

Steps for restoring galvanised metal

1. Inspection and cleaning

Thoroughly examine the metal surface for signs of damage or rust. Use a stiff-bristled brush and a solution of mild detergent or vinegar to remove dirt, grease, and any loose particles.

2. Rust removal

For minor rust spots, gently scrub the affected areas with a wire brush or fine-grit sandpaper until the rust is eradicated. For more extensive rust, consider using a commercial rust remover, following the manufacturer's instructions.

+91 7208055523

+91 7208055523

Help & support

Help & support