According to an industry report by Tech Sci Research, India's commercial vehicle market is expected to grow at a CAGR of 5.6% between FY2023 and FY2027. In FY2021, the country's commercial vehicles industry was valued at about $4 billion. This included a fleet of more than 1.6 million buses, of which 170,000 are public transport buses servicing 70 million people daily. Other types of heavy vehicles include goods vehicles, vehicle carriers, agricultural vehicles, trucks, cranes, and special vehicles.

The chief driver behind the growth of this segment is the use of heavy vehicles by end-use industries such as public transportation, construction, road transport, utilities, and others.

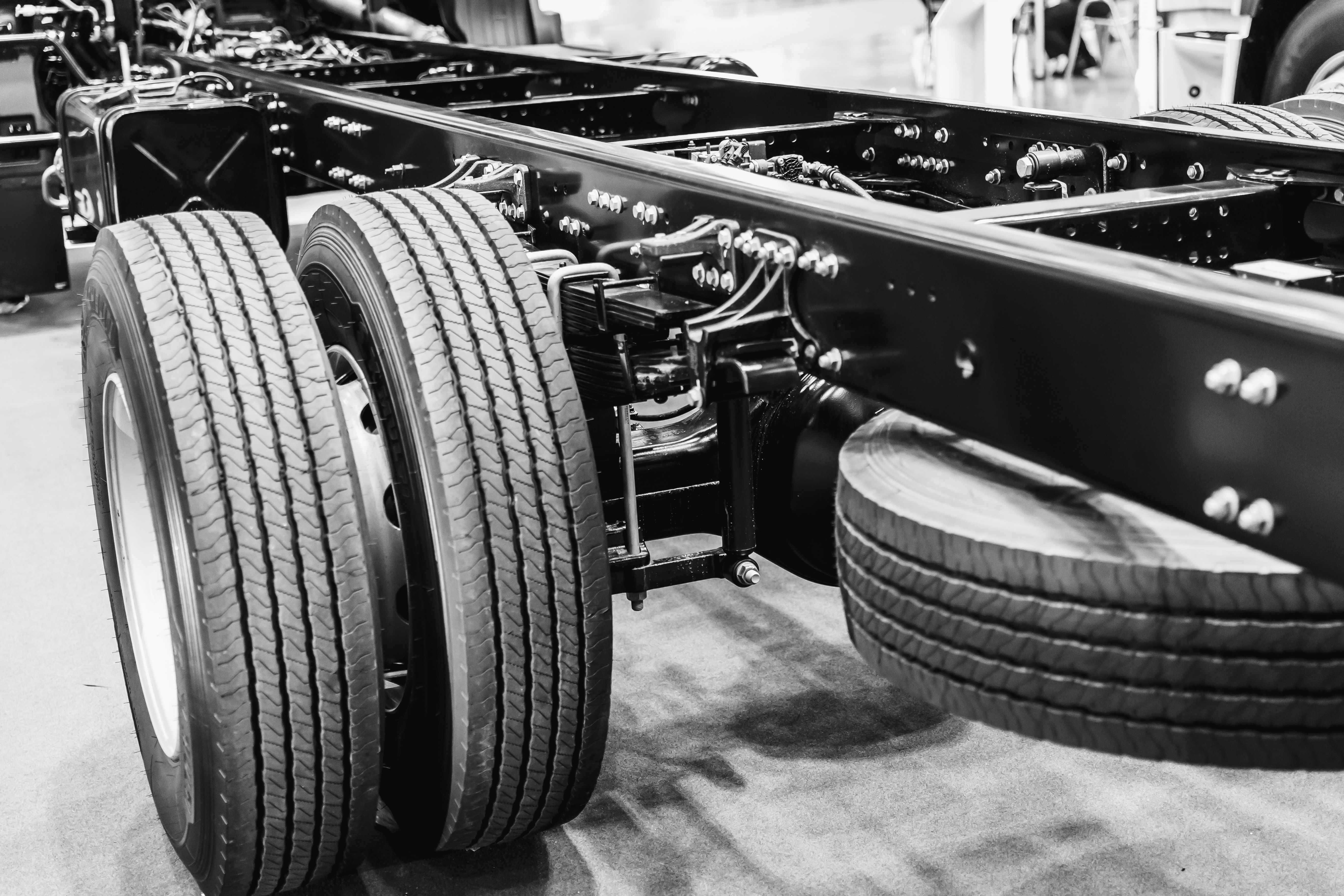

The manufacture of heavy motor vehicles (HMV) presents unique challenges. These include the need for raw and intermediate materials with a wide range of material properties, including higher yield strength, durability, fatigue-life, impact resistance, corrosion resistance, and high life-cycle cost, among others. In particular, heavy-duty HMV chassis need to be able to withstand sudden shock, twists, vibrations, and other stresses regularly, unlike chassis used in LMVs or two-wheelers.

It is thus important to carefully curate and select the right mix of steel types for the manufacture of HMV chassis. Let’s take a closer look.

Heavy vehicle chassis - Components and type of steel used

These are the different components that collectively form the chassis:

1. The frame of the chassis

2. Engine

3. Suspension system

4. Steering system

5. Braking system

6. Wheels and tires

7. Transmission system – clutch, gearbox, etc.

Chassis frame

The frame is the most important part of any vehicle, as it provides support and strength for the other components. The frame is made out of high-strength steel(HSS).

This type of steel has good resistance to wear, fatigue, and corrosion, and is stronger than low-alloy high-strength steel, but is not as strong as advanced high-strength steel (AHSS).

Engine

The steel used to make the engine block is more important than that used to make the pistons, and cylinder head, since it holds all other parts together.

As the engine is the main source of power for an HMV's drivetrain system, high-strength low alloy or HSLA steels are the ideal choice. HSLA steels have a higher yield strength than standard steels, which means they can be used under rough conditions without fracturing or cracking. This makes them a good fit for automotive applications where there's a lot of shock loading on the engine block.

As an alternative, an engine block can also be made from cast iron, which is a hardy, heavy-duty alloy of iron and carbon. It has a higher melting point than plain iron, which makes it stronger.

Suspension

+91 7208055523

+91 7208055523

Help & support

Help & support