In construction, rendering shields exterior walls from weather elements. Conversely, plasters serve as finishing coats, smoothing surfaces and creating a polished look. Beyond their practical functions, renders and plasters are vital components in the design, allowing for creative expression through texture, colour, and pattern. From traditional stucco finishes to modern acrylic renders, these materials offer versatility and adaptability, catering to diverse architectural styles and design preferences. In interior design, plasters contribute to the ambience of a space, providing tactile and visual interest. Discover top-tier industrial materials by registering on our platform today.

Cement renders

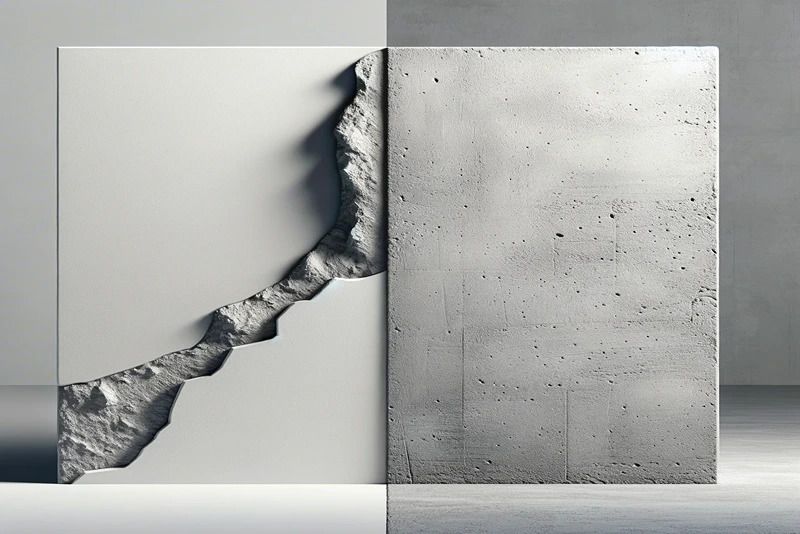

Cement-based renders are composed of cement, sand, and sometimes lime, mixed with water to form a paste that adheres to surfaces. Traditional cement render is the most basic form of cement and sand.

Polymer-modified render incorporates additives to improve flexibility and adhesion, making it suitable for challenging substrates.

Acrylic render contains acrylic polymers, enhancing flexibility and water resistance while providing a smooth finish.

+91 7208055523

+91 7208055523

Help & support

Help & support