Steel fabrication is crucial for small businesses due to its versatility and durability in constructing various products and infrastructure. However, small businesses face significant cost challenges in this area. They encounter high initial investment costs for specialised equipment like welding machines and cutting tools, need help recruiting and retaining skilled labour, and contend with fluctuating material prices. Additionally, meeting regulatory standards adds another layer of expenses. Overcoming these obstacles demands careful financial planning, strategic investments, and a focus on operational efficiency to maintain competitiveness in the market.

Material costs:

Types of steel: steel fabrication involves using various types of steel, each with unique properties and costs. Common types include carbon steel, stainless steel, and alloy steel. Steel costs vary significantly based on factors such as composition, grade, and market demand.

Labour costs:

Skilled labour expenses: skilled labour is crucial for successful steel fabrication but comes with expenses. Welders, fabricators, and technicians with specialised skills command higher wages, contributing to labour costs.

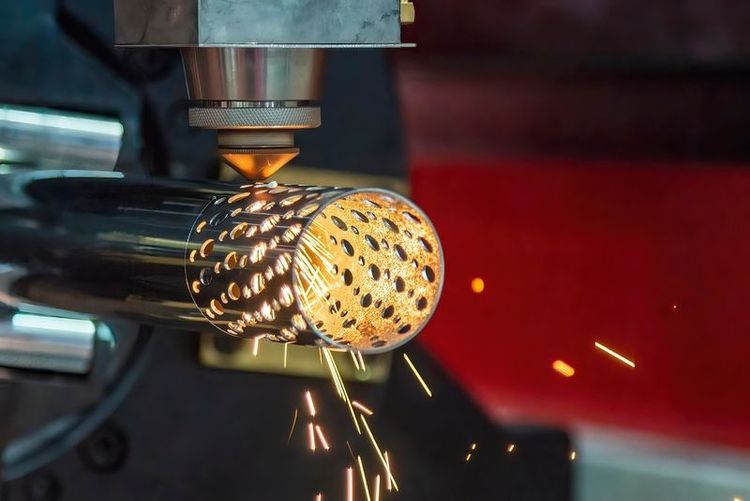

Productivity impact: the productivity of skilled workers directly influences fabrication efficiency and, consequently, overall costs. Efficiency in welding, cutting, and assembly tasks can significantly impact labour expenses.

+91 7208055523

+91 7208055523

Help & support

Help & support