Original Equipment Manufacturers (OEMs) face several challenges when managing their cash. These problems can make it harder to keep their business running smoothly.

A clear understanding of cash flow involves monitoring:

Cash inflows: revenue from sales, client payments, and financial inflows from other sources like loans or investments.

Cash outflows: payments for raw materials, labour, machinery, and operational expenses.

Let's break down some of the common challenges faced by OEMs:

Late payments from customers: OEMs often sell their products to customers who take a long time to pay, sometimes weeks or months after receiving the goods. This delay extends their sell cycles, creating a gap where the company has spent money but hasn’t received any return. Without clear agreements on buying transactions and payment terms. As a result, OEMs must look into trade credit with partners, using unsecured working capital from financial institutions to manage this period effectively.

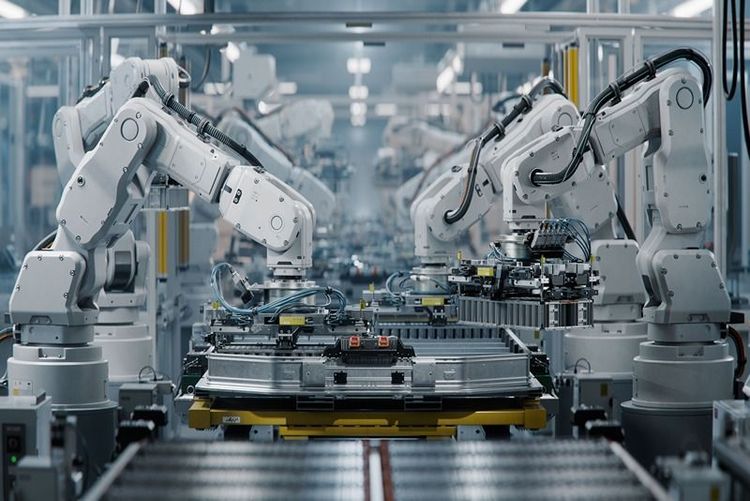

High upfront costs: OEMs must spend a lot of money at the start of production, buying materials, paying workers, and keeping machines running. They need to pay for these things before their customers pay them, which puts pressure on their available cash. For some, the solution is leveraging off-balance-sheet financing, 30-day credit options, to manage seasonal demand and maintain a steady cash flow.

+91 7208055523

+91 7208055523

Help & support

Help & support