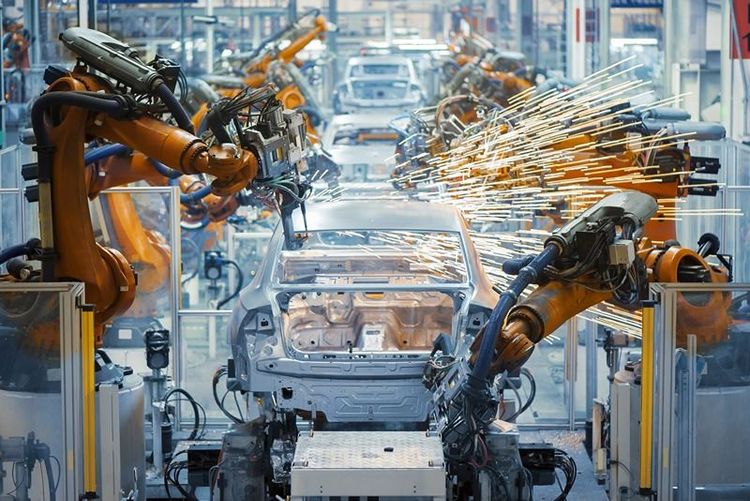

Welding plays a crucial role in auto parts manufacturing, particularly for Indian MSMEs focused on quality and durability in steel components. Steel remains a primary material in vehicle construction, so precise welding ensures robust, long-lasting parts. This blog offers insights into best practices for welding steel aimed at MSMEs.

Select the right welding process

In auto parts manufacturing, different welding techniques are used based on the type of steel and component. Below are the commonly employed methods:

MIG Welding (Metal Inert Gas): Ideal for high-volume production, MIG welding involves a wire-fed process, making it faster and suitable for joining thicker metals. It is widely used in automotive manufacturing for components such as body panels and interior parts. Try Ador Automig-1 ER70S-6 C-Mn Steel MIG Welding Wire, available on the JSW One platform, for a reliable process.

TIG Welding (Tungsten Inert Gas): TIG welding produces precise, clean welds, especially for thin, intricate parts. It’s frequently used for smaller, more delicate automotive parts, such as pipes and fuel tanks. For this purpose, Ador Tigfil ER70S-2 C-Mn Steel TIG Welding Wire is an excellent choice.

Resistance Spot Welding: Often used for joining sheet metal in cars, spot welding is highly efficient, ensuring fast production. It is typically employed for tasks such as welding chassis components and body frames.

+91 7208055523

+91 7208055523

Help & support

Help & support