There are different types of steel cladding sheets that are coated with metals like zinc or other alloys, used in construction because of the numerous benefits. Cladding refers to a material or layer that is applied to the exterior of a building or structure to provide protection, insulation, or decorative purposes. These cladding sheets have become an asset in the construction industry, from enhancing structural integrity to providing weather resistance and aesthetic appeal.

Benefits of steel cladding sheets in construction projects

How are steel sheets galvanised?

There are two methods for producing galvanised sheets:

Hot-dip galvanising: This is the most common method and involves dipping the steel sheets into a bath of molten zinc. The sheets are then cooled to solidify the zinc coating.

Electroplating: This process involves passing an electric current through the steel sheets immersed in zinc salts. Here's how it typically occurs:

Steel's potential is around -400 millivolts (mV) compared to a standard reference called the Saturated Calomel Electrode (SCE), the benchmark for measuring potentials. This means steel is somewhat anodic and tends to give away electrons, making it react with its surroundings in a certain way.

The potential measures how eager these materials are to give away their electrons. When a material gives away electrons, it becomes 'anodic', making it more willing to interact with other substances.

On the other hand, electroplated zinc, a layer of zinc applied to another material through electroplating, has a potential of around -980 mV when compared to the same SCE reference. The zinc ions are attracted to the steel sheets and form a layer of zinc on the surface.

Benefits

1. Strengthening structural integrity

Steel cladding sheets are ideal for construction as they improve the structural integrity of buildings with their high tensile strength and load-bearing capabilities. They reinforce the primary structure, distribute loads evenly, and help buildings withstand external pressures, making them perfect for areas with extreme weather conditions.

The popular thickness of galvanised sheets is 0.5-1.5mm. Our website offers galvanised steel sheets of thickness 0.5-3mm. On the other hand, Colouron+, a pre-painted galvalume coil, is a lightweight, high tensile sheet. It offers a yield strength of minimum 550 mpa and 770 mpa.

2. Weather resistance

Steel cladding sheets protect buildings from harsh weather conditions, resisting corrosion, fading, and deterioration caused by moisture, UV rays, and pollutants. They require less maintenance and keep the building's exterior intact. The Colouron+, Pragati+ and galvanised products are known for their corrosion resistance, thereby increasing the lifespan of the products.

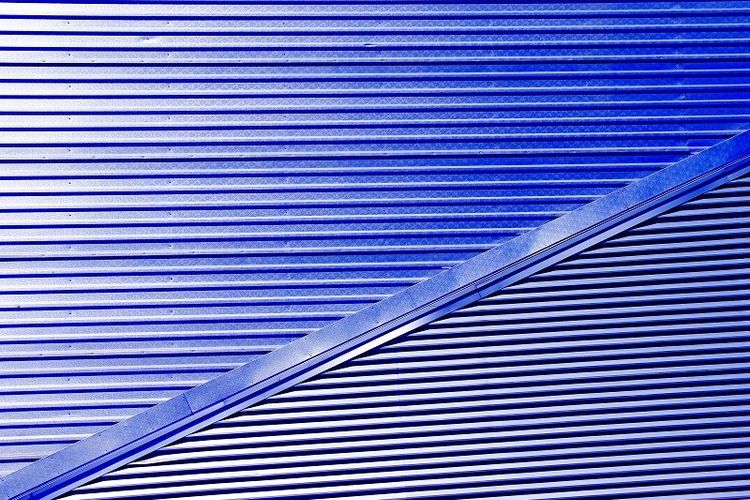

3. Aesthetic appeal

Steel cladding sheets offer architects the ability to create visually stunning facades, with a range of colours, textures, and finishes. This design freedom allows buildings to align with their intended purpose and surroundings.

4. Durability and longevity

Steel cladding sheets are a good choice for construction. They can extend a building's lifespan with minimal maintenance, saving on repair costs and reducing environmental impact.

5. Energy efficiency

Steel cladding sheets with insulation systems can enhance a building's energy efficiency and reduce energy consumption. This helps regulate indoor temperatures, resulting in cost savings.

6. Quick installation

Steel cladding sheets are a fast and efficient alternative to traditional building materials like brick, stone, and wood. Their modular design speeds up assembly, reduces labour costs, and minimises disruptions to surrounding areas. Ideal for urban or heavily populated regions.

Applications

Roofing: Steel cladding sheets are often used as roofing materials due to their excellent strength-to-weight ratio, corrosion resistance, and longevity.

Industrial buildings: Steel cladding sheets are commonly used in the construction of industrial facilities, such as factories, warehouses, and distribution centres. They provide a cost-effective solution for large spans and can be quickly installed.

Commercial structures: These sheets are employed to construct commercial buildings like shopping malls, office complexes, and retail outlets.

Agricultural buildings: Steel cladding sheets are used for constructing agrarian buildings like barns, sheds, and storage facilities. They offer protection for crops, machinery, and livestock.

Residential homes: In residential construction, steel cladding sheets can be used for exteriors and roofing. They add a contemporary touch to homes while providing long-lasting protection.

Sports facilities: Sports complexes, stadiums, and arenas often use steel cladding sheets for roofing and façades due to their structural integrity and aesthetic appeal.

Educational institutions: Schools and universities may incorporate steel cladding sheets in their construction, offering durability and architectural versatility.

Healthcare facilities: Steel cladding sheets can be used to construct hospitals and medical facilities, providing a clean, modern appearance and easy maintenance.

Transportation infrastructure: Steel cladding sheets can be applied in constructing transportation hubs, such as airports and train stations, to create visually appealing structures that withstand heavy foot traffic.

Renovations and retrofitting: Steel cladding sheets can be used in renovating or retrofitting existing structures to give them a modern makeover or improve their energy efficiency.

These sheets have revolutionised how architects and builders approach construction, from fortifying structural integrity to enhancing aesthetic appeal and energy efficiency. As sustainable practices and innovative design continue to shape the industry, steel cladding sheets are a perfect amalgamation of form and function.

Buy online

Mild SteelStructural SteelTMTCementJSW One MSME

About usBlogsSitemapJSW One TMTPolicy

Terms & conditionsPrivacy policyReturn policyBanking partner

+91 7208055523

+91 7208055523

Help & support

Help & support