Steel is roll-pressed at temperatures exceeding 1,700˚F, at which the 3-dimensional arrangement of atoms in the crystalline metal are permanently reoriented to increase ductility while lowering excess hardness. In this process, molten hot steel slabs are passed through a series of rotating rollers, which render the metal defect-free and the stock is compressed into desired shapes and dimensions. The metal is then left to cool. The resulting material is “hot rolled” steel. This steel has a myriad of applications across industries.

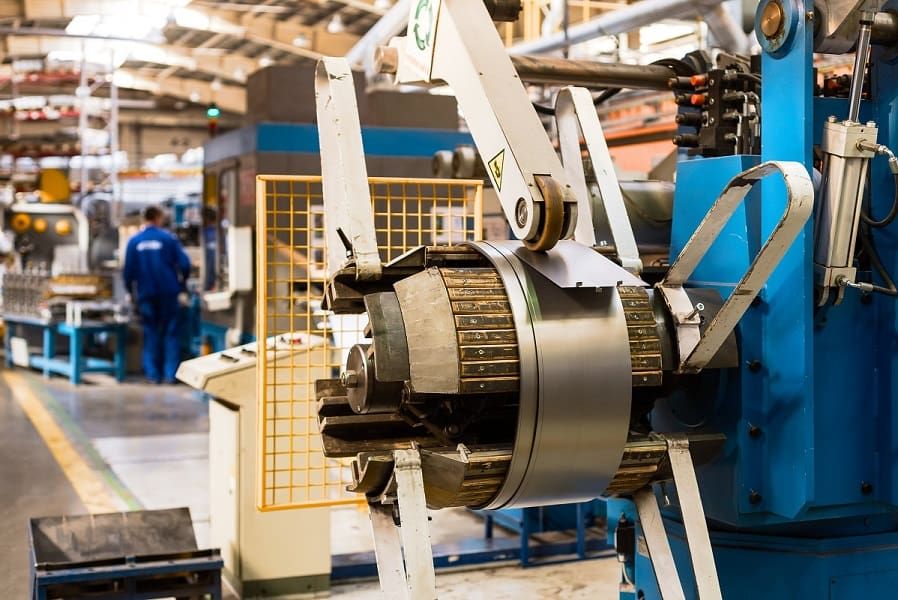

There are many steel products and parts that require steel with precise dimensions and higher surface quality than hot rolled steel. With this in mind, existing hot-rolled steel is further compressed, squeezed, turned, precision ground, and polished into desired shapes and sizes. All of this happens at room temperature and only mechanical strength, no heat, is employed. The end product is a more refined material- cold rolled steel (or CR steel).

+91 7208055523

+91 7208055523

Help & support

Help & support