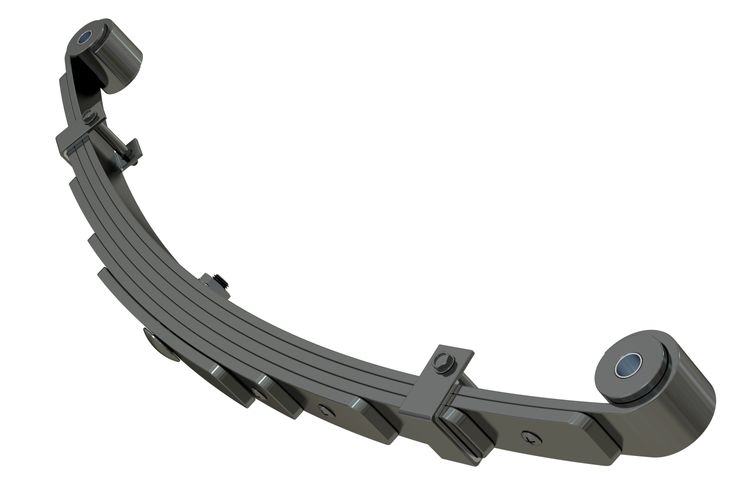

Leaf springs

- Description: leaf springs, also called carriage springs or semi-elliptical springs, consist of multiple layers or ‘leaves’ of spring steel of varying lengths stacked together and secured at the centre.

- Function: they support the vehicle's weight and provide stability by distributing the load evenly along the length of the spring.

- Variants: leaf springs can have different configurations, such as mono-leaf (single leaf), multi-leaf (multiple leaves), and parabolic springs (progressively tapered leaves).

- Advantages: leaf springs are robust, simple in design, and well-suited for heavy-duty applications like trucks and SUVs. They offer good load-carrying capacity and durability.

Types of materials in steel springs

The prevalent material utilised for suspension springs is steel, prized for its robustness, endurance, and cost-effectiveness. This resilient and rigid substance can endure substantial impacts and loads while resisting deformation.

High-carbon steel is frequently employed in coil springs for its durability and compression capability. Conversely, leaf suspension springs utilise lower-carbon steel, which is renowned for its ductility and enables easy formation into leaf springs' required curved shape.

- Alloy steel suspension springs

Alloy steel incorporates chromium, nickel, and vanadium, enhancing its strength and longevity beyond standard steel. This spring type is often favoured for high-performance vehicles such as race cars, luxury sports cars, and heavy-duty trucks. Alloy steel suspension springs exhibit resilience against heavy loads and retain their performance even in harsh conditions, rendering them well-suited for rigorous applications.

Tips for maintaining car springs

Regular inspection

- Visual checks: look for signs of wear, such as cracks, distortion, or corrosion.

- Listening for unusual noises: pay attention to any squeaks or grinding sounds, which could indicate problems with the springs.

Cleaning and lubrication

- Removing dirt and debris: use a brush or compressed air to clean away dirt and debris that can cause friction and wear.

- Lubricating contact points: apply a suitable lubricant to the contact points to reduce friction and prevent rust.

Preventing corrosion

- Rust prevention techniques: utilise rust inhibitors or coatings designed to protect steel from corrosion.

- Protective coatings: consider applying a protective coating such as paint or galvanisation to create a barrier against moisture and corrosion.

Proper loading and weight distribution

- Avoiding overloading: ensure that the springs are not subjected to loads beyond their capacity to prevent damage.

- Balancing weight distribution: distribute weight evenly across the springs to avoid excessive stress on any particular area.

Temperature considerations

- Effects of extreme temperatures: extreme heat or cold can affect the performance and integrity of steel springs.

- Mitigating risks: store and use the equipment in environments with moderate temperatures whenever possible. Consider using heat-resistant or insulated materials if exposure to extreme temperatures is unavoidable.

Springs are vital in handling and stability, reducing body roll during cornering and maintaining tyre contact with the road for improved traction and control. In tandem with other suspension components like shock absorbers or dampers, springs help control body motion, ensuring stability and safety under various driving conditions. Their design and tuning can be tailored to specific vehicle applications and driving preferences, providing adaptability and performance across road surfaces.

+91 7208055523

+91 7208055523

Help & support

Help & support